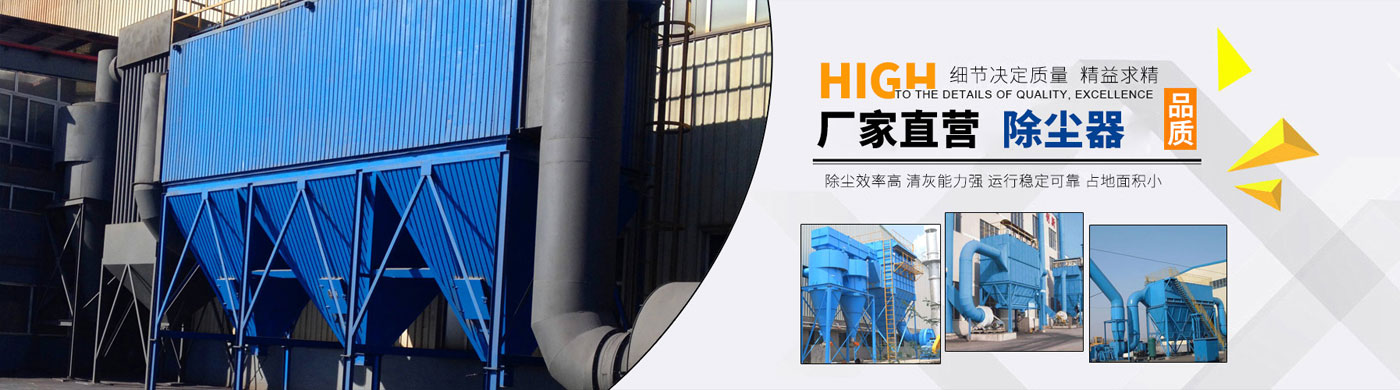

Boiler dust collector is the main force of the current governance environment, its scope of application and wide, from the air a thousand to hundreds of thousands of conditions, most of them are the boiler bag type dust remover, it in the new operation should pay attention to the matters are as follows:

1、处理风量和各测试点压力与温度是否与设计相符合.

1, the treatment of air flow and the test point pressure and temperature is consistent with the design.

2、风机的旋转方向、转速、轴承振动和温度.

2, the rotation direction of the wind turbine, speed, bearing vibration and temperature.

3、工作人员也要注意袋室结露情况是否存在,排灰系统是否畅通.防止堵塞和腐蚀发生,积灰严重时会影响主机的生产.

3, the staff to bag room condensation is there, rows of grey system is smooth. To prevent the occurrence of blockage and corrosion, serious ash deposition will influence a host of production.

4、清灰周期及清灰时间的调整,这项工作是左右捕尘性能和运转状况的重要因素.清灰时间过长,将使附着粉尘层被清落掉,成为锅炉除尘器除尘布袋泄漏和破损的原因.如果清灰时间过短,除尘布袋上的粉尘尚未清落掉,就恢复过滤作业,将使阻力很快地恢复并逐渐增高起来,最终影响其使用效果.

4, cleaning cycle and cleaning time of adjustment, this work is about catching dust performance and operating status of the important factors. Cleaning time is too long, will enable the attachment of dust layer is pure to fall off and become boiler precipitator dust bag leakage and breakage reasons. If the cleaning time is too short, dust bag dust is not clear to fall, on the restoration of the filtering operation, will enable the resistance quickly recovered and increased gradually up, and ultimately affect the effect of its use.

5、锅炉除尘器的安装情况,在使用后是否有掉袋、松口、磨损等情况发生,投运后可目测烟囱的排放情况来判断.

5, boiler precipitator installation, in use is off the bag, Tricholoma, wear, put into operation can visually chimney emissions to judge.